Mark Andy University

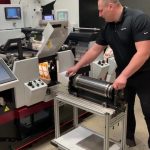

Mark Andy University is your destination for industry-leading training, designed to build confidence, improve efficiency, and strengthen your pressroom performance. Held at our state-of-the-art demo center in Chesterfield, MO, each course blends classroom learning with hands-on pressroom experience, all lead by certified Mark Andy instructors.

Whether you are just getting started or looking to sharpen or expand your skills, we offer tailored training for both operators and maintenance technicians.

Program Highlights:

- Location: Mark Andy Headquarters | Chesterfield, MO

- Duration: One Week (Monday noon – Friday noon)

- Format: Classroom instruction + hands-on pressroom training

- Courses Include:

- Introductory and advanced press operation

- Routine and advanced maintenance training

- Deliverable:

- Participants receive official Mark Andy Certification

Why Attend?

- Learn from certified Mark Andy experts

- Gain practical skills you can apply immediately

- Improve pressroom performance and reduce downtime

- Receive documentation of training for company compliance

- Network with peers in a collaborative environment

Upcoming Classes:

2026 classes coming soon!

Sample Agenda:

This is an example agenda for the flexo classes. Your class may not follow this exact format.

12:00 – 12:30 – Welcome lunch & introductions

12:30 – 12:45 – Agenda Review

12:45 – 1:30 – Safety Review & Facilities Tour

1:30 – 3:30 – Anilox Rolls

Doctor Blades & Doctor Blade Holders

Ink Pans and Meter Rolls

Plate Roll Discussion

Plates and Tapes

UV and WB Inks

Overview of ERC (Elect Reg System)

Overview of Web Tension Theory

3:30 – 3:45 – Break

3:45 – 4:45 – Loading an Ink Station

Setting Proper Ink & Impression

Setting ERC & ERC Details

4:45 – 5:00– Wrap Up & Class Ends

6:30 – 8:00 – Welcome Dinner

8:00 – 8:30 – Basic Machine & Safety Review

8:30 – 10:00 – Trainee’s Practice Loading, Setting Impression & Printing 1 Station on Press

10:00 – 10:30 – UV System and Hot Air System Review

10:30 – 11:00 – Deep Dive on ERC

ERC Controls & Functions

Using Gain, Windowing, Vari-Print

11:00 – 11:30 – 4C Job Demonstration

11:30 – 12:30 – Lunch & Break

12:30 – 1:30 – Unwind Overview

Setting Unwind and Infeed Tensions

Substrate Review

Web Guide Overview

Corona Treater Overview

1:30 – 2:00 – Putting a Roll of Material on Press

Web Path Overview

Splicing a Roll of Material

Setting the Web Guide

Setting Unwind Tension

How to Deal with “Bad Rolls”

Setting Infeed Pacing Tension

2:00 – 2:30 – Exit Pacing & Rewind Overview

Setting Exit Pacing

Rider Roll Usage

Setting Rewind Taper & Tension

Removing a Roll from the Rewind

2:30 – 2:45 – Break

2:45 – 3:00 – Camera System Overview

3:00 – 4:45 – Trainee’s Practice Running 4c Job

4:45 – 5:00 – Wrap Up & Class Ends

8:00 – 8:30 – Recap of Day 1 & 2

8:30 – 9:00 – Review of Proper Way to Mount Plates

Cylinder Selection

Measuring for Center

Tape Types

Plate Types & Tint Sleeves

9:00 – 10:00 – Trainee’s Mount Plates

10:00 – 11:30 – Trainee’s Practice Running 4c Job

11:30 – 12:30 – Lunch & Break

12:30 – 1:30 – Vertical Slot Diecut Review

QCDC Diecut Review

Semi-Rotary Diecut Review

Review of Solid Tools and Mag Die Plates

WWU Overview

Types of Matrix Removal Techniques

1:30 – 2:45 – Mounting a Mag Plate

QCDC Cart Review

Using Tooling Adaptors

Loading QCDC

Setting Diecut Pressures

Die Cutting ERC Review

Adjustable Anvil Review

RD Score Discussion

Vertical Slot Die Cutting Demonstration & WWU

2:45 – 3:00 – Break

3:00 – 4:45 – Trainee’s Load Dies and Diecut

4:45 – 5:00 – Wrap Up & Class Ends

8:00 – 10:00 – Trainee’s Set Up the Machine from Scratch

10:00 – 10:30 – Lamination Overview

Different Types of Laminates

Understanding Curl & Setting Tensions

10:30 – 11:30 – Delam Relam and Web Turn Bar Review

Cold Foil Overview

Slitting Systems Discussions

Shear Slitting

Crush Cutting

Razor Blades

Trim Removal Techniques

Sheeting & Conveying Review

11:30 – 12:30 – Lunch & Break

12:30 – 2:30 – Cold Foiling a Job

Laminating a Job

Delam Relaming & WTO a Job

Slitting, Crush Cutting a Job

2:30 – 2:45 – Break

2:45 – 3:45 – Proper Clean Up & Storage Methods

3:45 – 4:45 – Final Exam Part 1

4:45 – 5:00 – Wrap Up & Class Ends

6:30 – 8:00 – Closing Dinner

8:00 – 10:00 – Final Exam Part 2

10:00 – 11:00 – Q&A and Review of Open Items

11:00 – 11:30 – Graduation Ceremony

11:30 – Class Concludes

Ready to Enroll?

Spots are limited and classes fill quickly. Reserve your seat now.