Singlepass Success: Eliminating Waste & Creating Value Inline

In an age of uncertainty, the label and packaging industry has generally continued to thrive, as converters large and small have reported increases in production, as well as shifts in market segments that are reflective of the environment today. All the while, these businesses have maneuvered the tall order of increasing production during a time when extra precautions are essential to ensure employee safety and operational efficiency.

Despite increased pressure to perform under current conditions, print service providers must also answer the pre-pandemic challenges plaguing effectiveness. Faster lead times, skilled labor shortages and cost-effective solutions for short run, to name a few, remain obstacles affecting overall productivity. As such, label manufacturers are increasingly seeking avenues to gain a competitive edge. In this case, there is one common denominator that can create a more competitive landscape: time. But how can one create more time?

It can be said that there are a small handful of goals that all businesses, no matter their industry, strive to achieve. On-time delivery of a quality product at a profit. It’s the most basic business model in existence by nature and certainly one applicable in this industry. Again, time is the subtle variable that’s been deemed an obstacle to overcome. So what can converters do to ensure these goals are being met, or better yet surpassed?

As label and packaging professionals, the term ‘waste’ can carry dual meaning. In its most simple definition, waste refers to a tangible, physical thing – material waste for example. But when evaluating the value and efficacy of an existing process, waste is a synonym for inefficiency. By striving to eliminate inefficiencies, non-value add activities – for example unnecessary workflow processes – are minimized allowing for an increased focus on activities that solely add value and are intrinsically proficient by design.

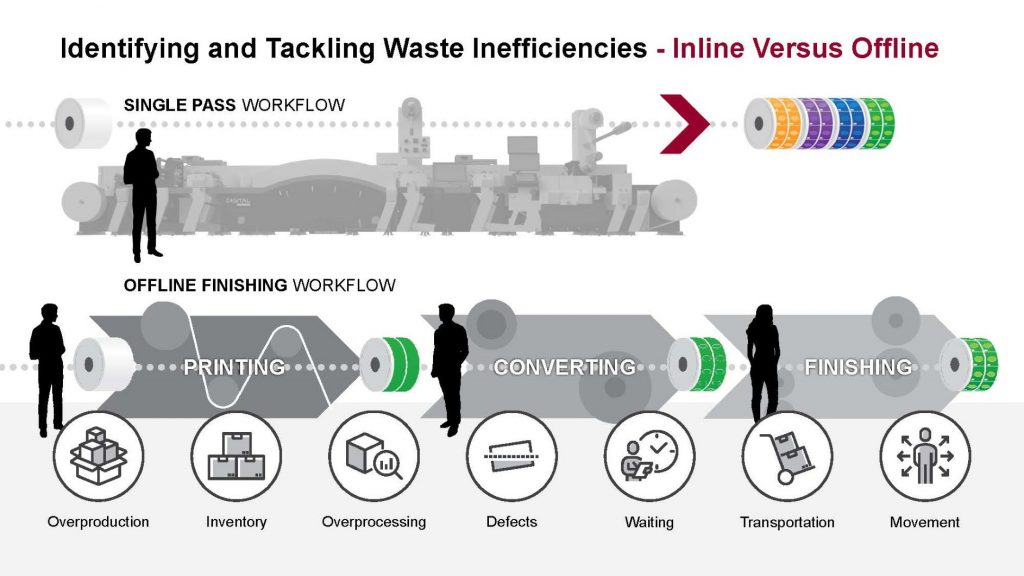

Removing the obstacles hindering the on-time delivery of high-quality labels at a profit starts with identifying the waste inefficiencies in a production environment. When comparing a single pass inline finishing workflow and multi-equipment and sometimes multi-pass offline finishing workflows, there are many straightforward inefficiencies that can be outlined in the latter.

Wastes in muda lean manufacturing have historically been identified in seven forms: overproduction, inventory, motion, defects, over-processing, waiting and transport. All of these waste categories can be identified in an offline finishing workflow, paving the way for an inline digital hybrid workflow to provide a solution for these inefficiencies. This provides end-users with a final product that was created through value-add processes only.

Overproduction & Inventory

Overproduction comes into play as press operators attempt to compensate for the waste and time during setup from each specific process: printing to converting to finishing, producing excess supply ‘just in case.’ This wasteful habit goes hand in hand with inventory, another identifiable waste metric. Business owners will see incurred costs in terms of both material and overhead for storage space. It is routine in the world of labels to overproduce a run, especially when digital equipment is not in a business’ arsenal and flexo is the only production means. The excess inventory is stored in hopes a repeat order is made without artwork modification.

Overprocessing & Defects

Overprocessing, or any component of a manufacturing process that is unnecessary, certainly applies by design in many industrial settings. Prepping an area and staffing for a piece of equipment that may not be needed is an applicable example. The other side of the coin to overprocessing is defects, which are more likely as increased variables are included in the production process. Defects lead to wasted processing efforts and loss in material costs.

Waiting

Waiting, the fifth waste, is simple: time spent where workers or machinery are not ideal. Do you observe dead time in your multi-step production process? If so, that is an identifiable waste that may need to be addressed to ensure lean manufacturing.

Transportation & Movement

Transportation and movement, the final two wastes in lean manufacturing, are quite similar when put under the lens of labels and packaging. Waste of transportation in label production would be moving a roll of labels from a press to finishing equipment and so on and so forth. The more unnecessary movements in the production process, the larger the opportunity for waste reduction with inline converting and finishing. The waste of movement is specific to workers in the production process and is essentially the human element of the production flow. By increasing the number of movements in a production workflow, there is an increased reduction in output – whether by workflow inefficiencies or even risk of overexertion and injury.

Eliminating Waste

The elimination of waste (a non-value added activity for which costs cannot easily be passed through to a customer) in a converter’s process enables businesses to deliver high-quality products at competitive prices in short lead times. An offline converting and finishing process is a non-value added step by nature. It’s similar to buying a home. Will your kitchen renovation provide added value? Yes, of course. But can you pass through the costs of the new inground pool added just a few years ago? No – buyers are historically not willing to invest more for certain projects.

Customers aren’t willing to pay additional costs to account for the investment level of the offline finishing process, including equipment, space, staffing, etc. And business owners frankly should not be willing to compromise these margins either. But by utilizing printing equipment that is more efficient, getting quality finished products out of the door at an increasingly rapid rate, the pass-through costs of the higher investment level become more attainable as more jobs can be added to the book of business.

Efficiency Through Inline Converting

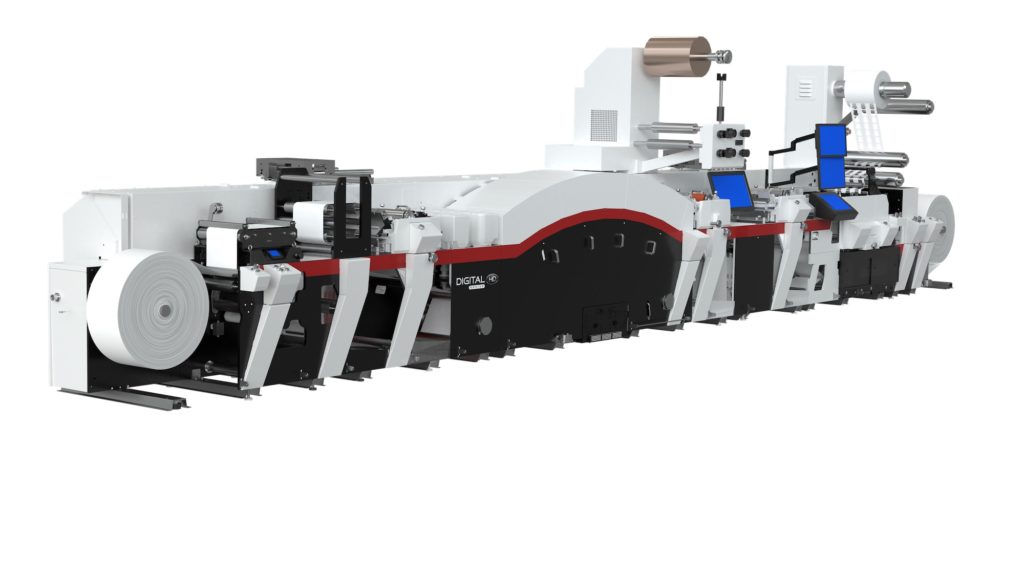

Inline converting is of course one of the leading advantages in narrow-web flexo printing. But as digital adoption rates continue to rise, it comes as no surprise that many of the leading press manufacturers have engineered solutions marrying digital engines and inline converting and finishing equipment. These single-pass hybrid solutions provide the best of both worlds: the ability to provide value-add benefits to customers like decreased lead times and product differentiation opportunities as well as the use of multiple print stations while adding stations for laminating, hot foil stamping, sheeting and more.

Circling back to the all-important question: how do we create more time? When comparing the two processes, customer throughput data routinely points to significant advantages in an inline workflow. Time savings of 55% has been reported by converters who have adopted inline hybrid equipment as a replacement to an offline workflow. The same converter reports over a one-year period, simply adopting an inline workflow increased gross margins upwards of 8%.

So, what does time mean to you? The variable nature of current market conditions favor the flexible, multi-use functionality of digital hybrid presses by utilizing the solution based on job mix. In presses with superior web transport capabilities and digital engine bypass bridges, converters can use solely the flexo printing components when it makes sense and easily transition back to either digital or digital hybrid production.

Want to learn more about an integrated, hybrid workflow? Mark Andy can help. Contact us today for more information.