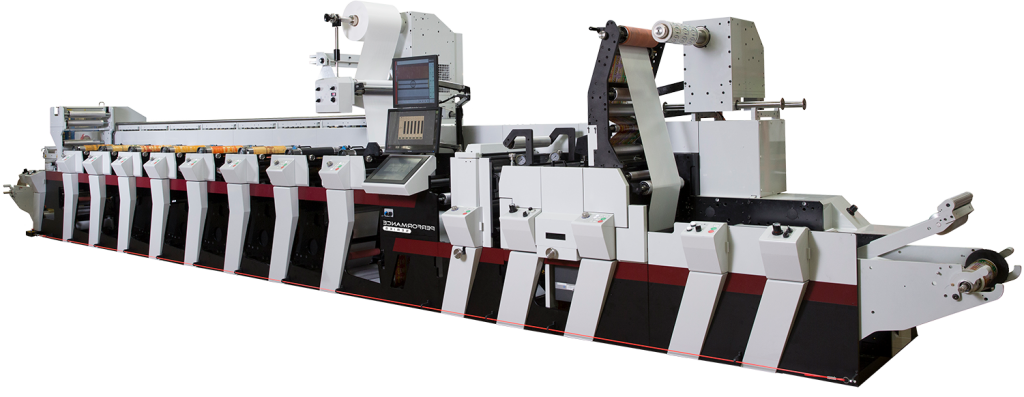

Technology that Delivers Peak Performance

The fastest selling platform press in narrow web history was developed with Business Responsive Technology to address your needs and impact your bottom line.

Over 1,000 worldwide installs place Mark Andy as a dominant force, stable provider and servicing authority of flexographic printing solutions.

Mark Andy AI packages support Industry 4.0 demands for enhanced automation.

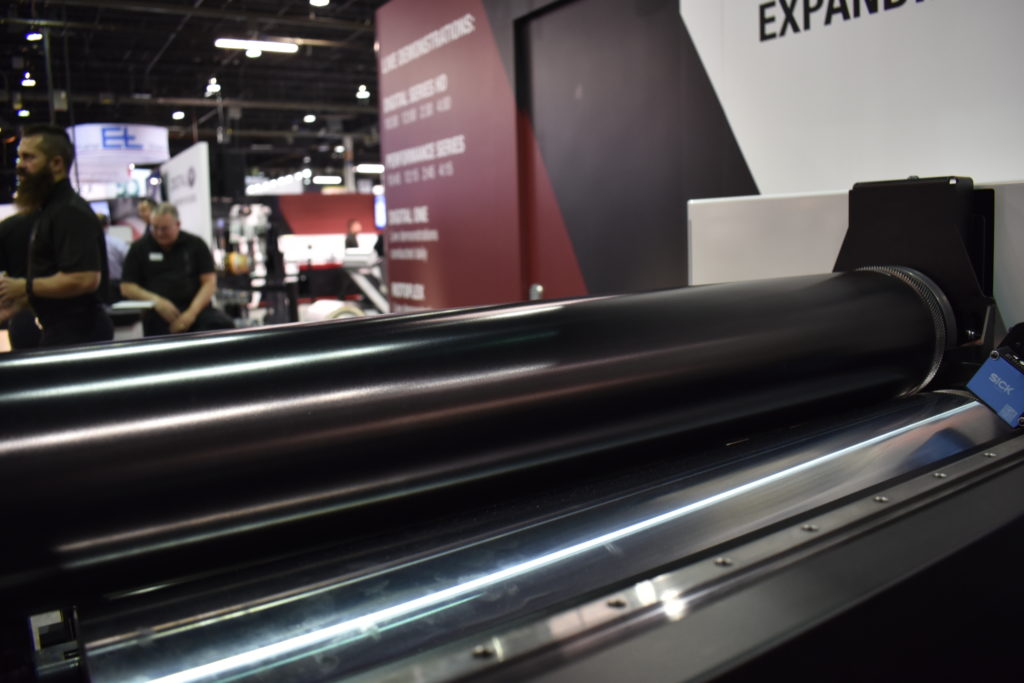

360-degree registration adjustment and controlled ink densities produce high quality dots in a simple and repeatable fashion. Maintain your quality job to job, year over year, even in different production facilities.

With the largest global service team in the industry, you are supported by Mark Andy to succeed. Beyond technical assistance, we offer our partners business development consulting, application expertise, and all the parts and consumables needed from a true Total Solutions Partner.

A Result of Passionate Engineering and Innovation

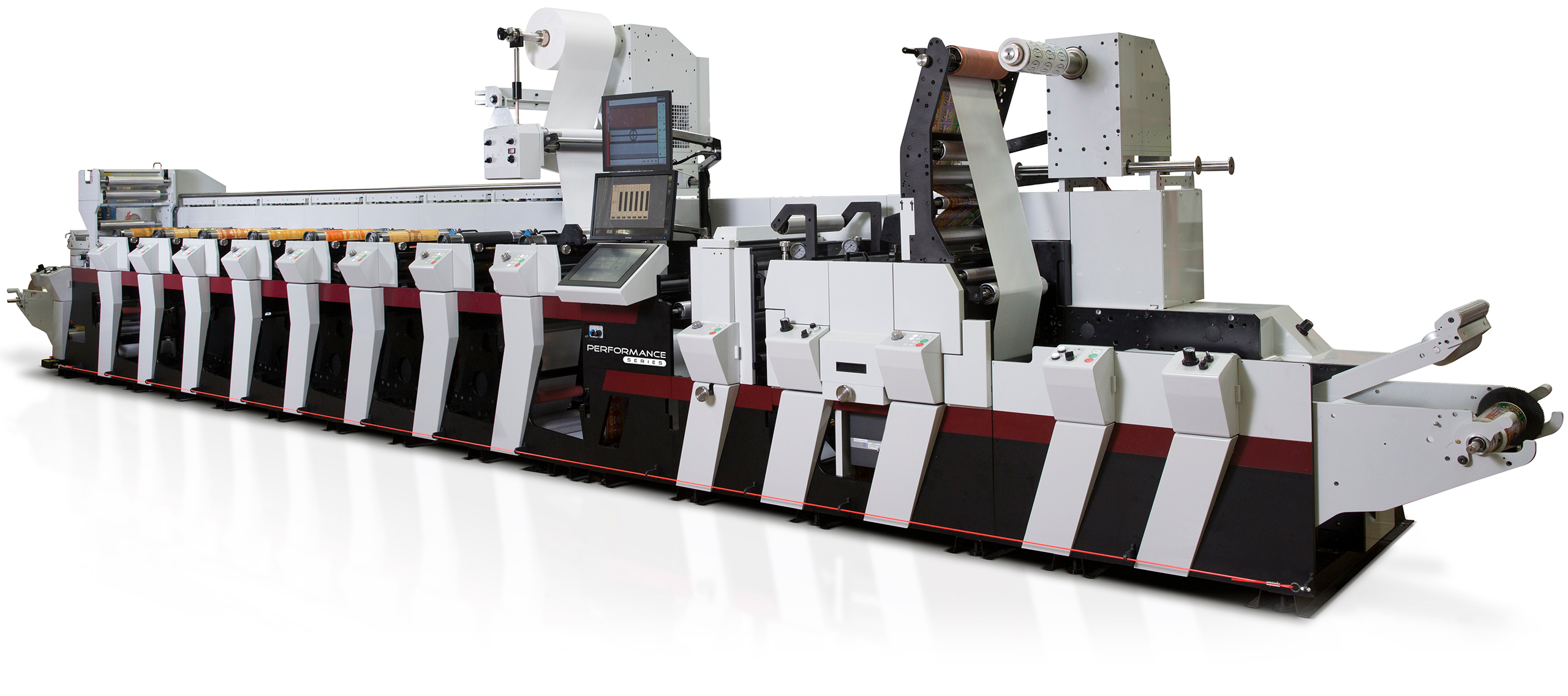

P9 Technical Specifications

Web Width

13/17/22/26 inch (330/430/558/660 mm)

Max Speed

1000 fpm (305m/min) with high speed configuration

Substrate Range

0.5 mil - 18pt (12-450 micron)

Print Repeat Range

5.5-24 inch (140-610mm)

Die Repeat

24 inch max (610mm max)

Unwind Capacity

40 inch (1016mm)

Rewind Capacity

40 inch (1016mm)

P7 Technical Specifications

Web Width

10/13/17/20/22 inch (250/330/430/508/558 mm)

Max Speed

1000 fpm (305m/min) with high speed configuration

Substrate Range

0.5 mil - 18pt (12-450 micron)

Print Repeat Range

5.5-24 inch (140-610mm)

Die Repeat

24 inch max (610mm max)

Unwind Capacity

40 inch (1016mm)

Rewind Capacity

40 inch (1016mm)

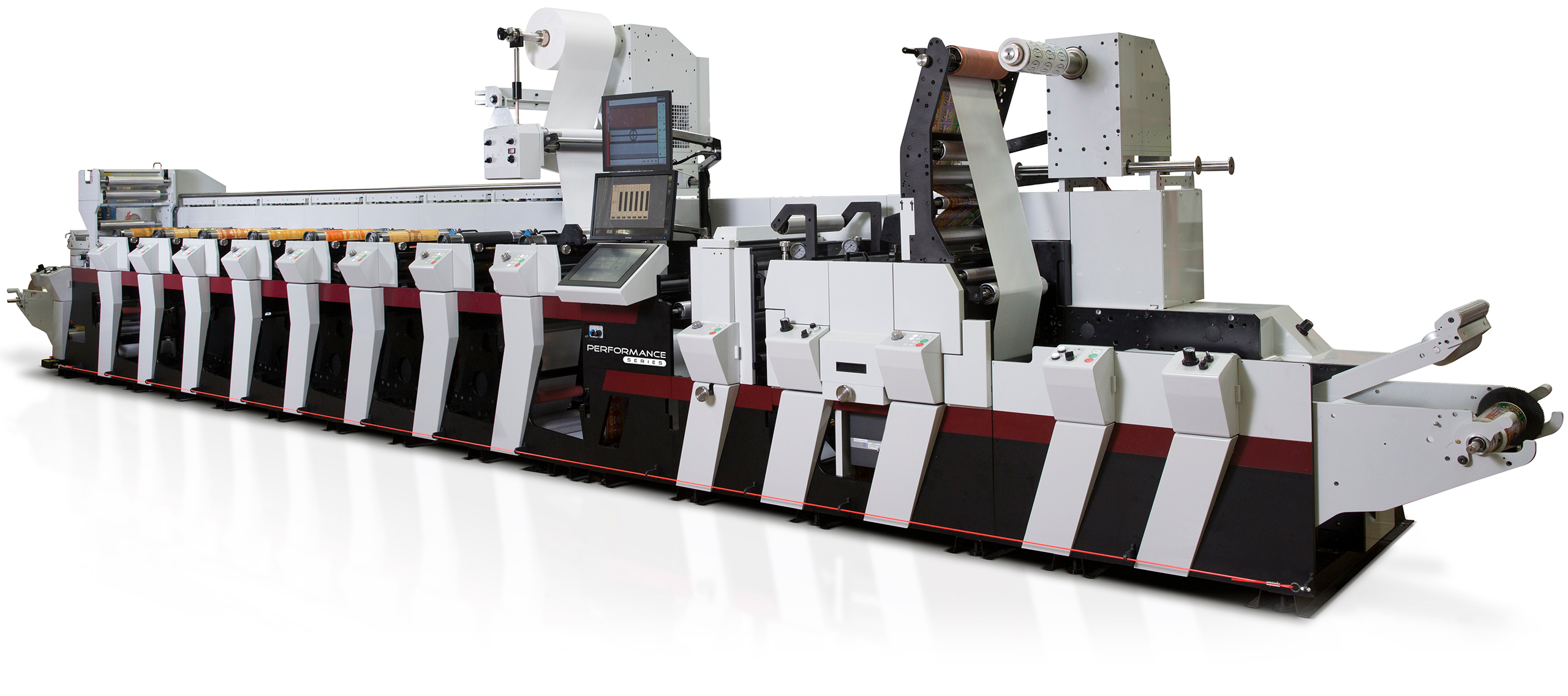

Complex Printing with Value-Added Enhancements

The Mark Andy Performance Series is industry-recognized for its versatility. Supporting the widest array of applications and substrates, the press is a smart investment in your printing operation.

Bottle Wraps

Film (Supported & Unsupported)

Prime Labels

In-Mold Labels

Lidding

Light Carton

Durable Industrial

Roll-fed Labels & Wraps

Shrink Sleeves

Tags & Tickets

Extended Content Labels

Flexible Packaging

Food Grade Flexible Packaging

Shrink

Expanded Gamut 8 Color Job

The Future of Flexo eBook

A look into the future of evolving narrow-web print technology and how converters can capitalize on industry growth

Get Your Copy

Driving High Levels of Performance

Continental Datalabel brings production consistency to multiple facilities with 3 Performance Series presses

Learn MorePerformance Series Overview Video

The P Series proves to be a two for one replacement over conventional flexo presses