Planning to Add Digital? We Have Some Tips

You are smart and savvy when it comes to running your label business. But is the digitalization of the label game giving you some worry? Don’t fret – we outlined some quick tips below to ease your mind.

Evaluate Your Book of Business

When updating your existing technology stack, it’s important to take a step back and think about your current customer needs as well as possible areas for diversification or growth. Higher-margin applications are becoming more standard on digital hybrid equipment. With converters running shrink sleeves and even extended content on their digital inkjet solutions, new doors are beginning to open for previously unattainable options without additional equipment. And having the ability to add those new offerings alongside the capability of producing variable data labels, there is ample room for business growth. By examining the current and future state of your business, you are ensuring a smart decision and sound investment in your operation.

Look Big Picture

When the investment is affordable upfront, it’s hard to continue hardware evaluations beyond the scope of that lower price. Converters should, however, be thinking about the total cost of ownership. This essentially boils down to how much revenue can be generated per shift. More productive machines mean more throughput and hybrid solutions mean less downtime, both a recipe for exponential value over time. Digital presses are certainly large investments, but they are also long-term investments. Having the most affordable solution does not always mean that you’re ending up with the most valuable option available.

Audit Your Finishing Department

Roll-to-roll, inline, nearline, the works. There are lots of different finishing options that match the many different ways converters send the final product to customers and manage their manufacturing processes. If your rewinders are at maximum capacity, it may make sense to elect for inline converting to give them a little room to breathe. Inline converting and finishing also can eliminate many of the inefficiencies that print shops have a hard time identifying without electing to pursue an audit.

And if your pressroom is set up for success with offline finishing, it’s imperative to evaluate the options available to ensure that your operation is as functional and wasteless as possible.

Ensure You Have the Right Tools

Every press has a supporting cast to make it as efficient as possible. With digital, making sure you have all the right pre-press resources can make a world of a difference. Both hardware and in the form of software.

Digital Series iQ is a fully integrated digital hybrid solution with production speeds up to 230 FPM. Low cost to print on DSiQ positions this press as the ideal solution for converters interested in single pass, production-level digital hybrid printing.

Digital Series iQ is a fully integrated digital hybrid solution with production speeds up to 230 FPM. Low cost to print on DSiQ positions this press as the ideal solution for converters interested in single pass, production-level digital hybrid printing.

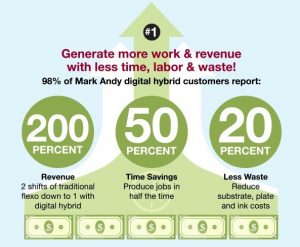

Don’t Knock Hybrid

We sometimes hear from prospects that they are just looking for digital and not hybrid. To that, we pose a simple question: “Why limit yourself?” When digital hybrid is an option and has the application range it does, it makes sense. Hybrid truly is the short and mid run solution for any and all narrow-web label and packaging work, unlike other conventional digital assets that excel in imaging and imaging alone. The technology can enable high-end label markets, all in a single pass, like shrink, indirect food contact, extended content constructions, durables, film and more.

Hybrid is simply the best of both worlds:all of the benefits of a digital press, plus everything your customers need from an embellishment perspective at peak productivity.

Conclusion

Ready to make new digital a reality in your operation? Contact a Mark Andy sales rep to get in touch.